| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : HSTECH

Model Number : AIS300

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 50 sets per month

Delivery Time : 15~20 work days

Packaging Details : Wooden package

Product Name : Inline THT DIP AOI After Wave Soldering

Warranty : 1 Year

Control : Touch Screen

Relay Brand : Schneider

Signal : SMEMA

Application : Electronic Assembly

Power Supply : AC220V

Weight : 800kg

Remote Control Automatic Inline THT DIP AOI After Wave Soldering With Dual XY Linear Actuators

Introduce

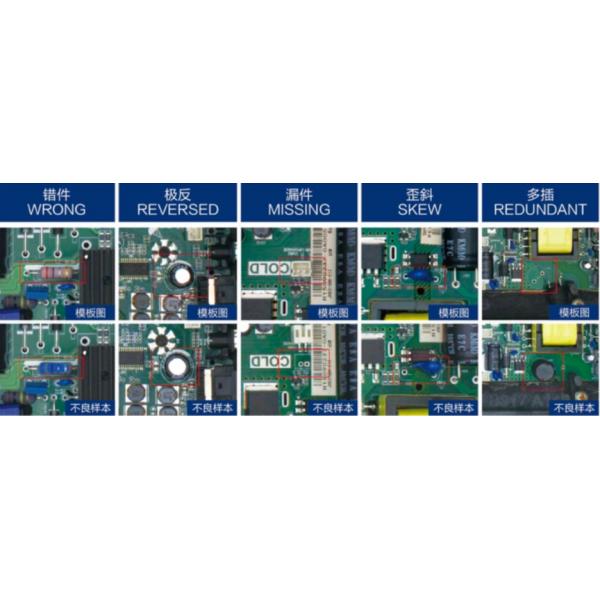

Before soldering, AOI can detect the defects of the device itself, such as missing parts or polarity, etc. After reflow soldering, A0| or after wave soldering, AO| can detect: tin connection, too little tin and too much tin, and no tin short-circuit solder ball leakage. -Polarity·shift foot bending wrong parts, AOI testing equipment after wave soldering. Vector analysis technology has set a new industry standard in the AO! industry for the following reasons: 1. The vector image is fully automatically generated, and any object on the PCBA can be taken as a MARK point, making programming more flexible; 2. Provides high-precision defect detection <high Precision positioning technology >;3. Provides extremely low false alarm rate.

1. No Golden Sample is required, only qualified products are required

2. No statistical modeling is required, and there is no need to run dozens of boards for fine-tuning.

3. Automatically generated "vector imaging" (not affected by temperature and focal length) can improve the accuracy, speed and high reliability of component identification and positioning during PCB board assembly.

4. Feature vector analysis (direct calculation of angles and size ratios), perfect combination with IPC standards

Specification

| Model | AIS300 | AIS301 |

| PCB Size | 50x50mm~430x380mm | 50x50mm~350x350mm |

| Thickness | 0.3~7.0mm | |

| Warping extent | <4mm | |

| Component height | Top 150mm, bottom 25mm | |

| Camera | 5MP,color,CCD | |

| Light source | RGB | |

| FOV | 45*37mm | |

| Resolution | 20um | |

| Inspection | ||

| Mounting components defect | Missing,rolling,offset,damage,skew,redundant,dirty. | |

| Solder defect | Excess,insufficient,bridge,no foot,missing solder,non-wetting. | |

| Other function | Bar-code,QR cod,OCR | |

| Speed | 0.23sec/fov | 0.25sec/fov |

| Software/Hardware | ||

| Operation system | Ubuntu 14.04 LTD 64bit | |

| Function | Remote control, Gerber file importing, training tool for new models | |

| Industrial PC | CPU intel i5,Independent Graphics Card,12G DDR,256SSD | |

| Display | 22 inch FHD LCD | |

| Motion | High accuracy linear actuator | |

| Power supply | AC220V,1KW | |

| Air pressure | >0.5Mpa | |

| Dimension(L*H*W) | 1100*1630*1350mm | 1100*1280*1300mm |

| Net Weight | 800kg | 700kg |

Features

A, Core algorithm—— Convolutional Neural Network Algorithm

Application and Innovation in industry

Human-like inspection

Better compatibility

Training algorithm model of super large sample set

High generalization

Super detection ability, lower false positive

Supporting user self-training model

B, High wear resistance

C, Large inspection area and high compatibility

D, High inspection rate and low false positive rate.

E, Marble base, more stable.

F, Dual XY linear actuators, high speed, high accuracy

Application

This inline THT AOI used after wave soldering machine in DIP production line,it used for Correcting the wrong units, which can reduce repairs and time. The passing rate can be improved efficiently. This machine widely used for inspecting TV mainboard,PC mainboard,power board,industrial control board,Mini household electronic appliances and other PCBAs.

About Packaging

|

|

Remote Control Automatic Inline THT DIP AOI After Wave Soldering With Dual XY Linear Actuators Images |